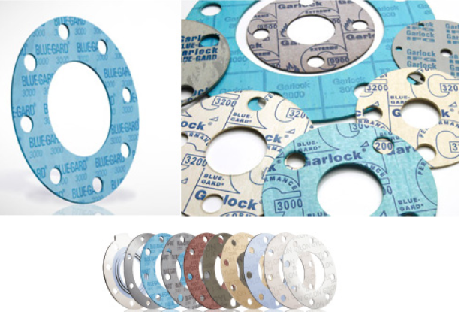

Gasketing is offered in wide range of non-asbestos materials including GYLON® restructured PTFE gaskets, an industry standard for resistance to aggressive chemicals, and its extreme grade gasketing with Flange Free™ anti-stick coating. A patented heat welding process enables the production of one-piece gaskets instead of separate segments spliced together. Our gasketing products include engineered low-load styles available in either sheet form or as discreet gaskets as well as materials to effectively seal metallic piping.

High Pressure Sheet (HPS) Gasket Material

Compressed fiber sheet gasket material, a stalwart of the Garlock product line, has been improved and expanded over the years. The materials have been reformulated and upgraded, and the HPS manufacturing process now uses an environmentally friendly non-VOC solvent. In addition, Garlock’s environmental controls now include a solvent recovery system that captures emissions and recycles them into the production process. Solvent recovery is used in the production of both high pressure sheet and GYLON.

GYLON

GYLON® gasketing is a family of flat PTFE gasketing materials manufactured to decrease the creep relaxation problems that usually plague PTFE products.

BLUE-GARD

The BLUE-GARD® Gasketing line offers a variety of elastomers to excel in a wide range of services.

2900 FAMILY

The Garlock 2900 is a family of compressed non-asbestos gasket materials, aramid fibers and PTFE sheets, ideal for utility and general service applications.

LEAK-GARD

LEAK-GARD Gasketing provides a tight, long-lasting seal in oil applications without gasket degradation.